In the fast-paced world of retail, effective inventory management is crucial for businesses to maintain profitability and meet customer demands. One essential aspect of inventory management is inventory serialization, a process that assigns unique identifiers to individual products or items. By implementing inventory serialization, retailers can gain granular control over their inventory, optimize operations, and provide an improved customer experience.

What is Inventory Serialization?

Inventory serialization involves assigning a unique identification code to each item in a retailer's inventory. These codes, often in the form of barcodes or RFID tags, enable businesses to track and trace products throughout their lifecycle, from production to sale. Each product becomes distinguishable with serialisation, allowing for accurate stock counts, efficient inventory control, and streamlined supply chain management.

Benefits of Inventory Serialization

Inventory serialization eliminates the possibility of duplicate or inaccurate entries, providing retailers with precise inventory data. Accurate inventory counts enable businesses to make informed decisions about stock replenishment, minimizing overstocking or stockouts and reducing associated costs.

Serialization enables end-to-end product traceability, allowing retailers to monitor products' movement through the supply chain. In product recalls, serialization ensures prompt identification and removal of affected items, reducing potential risks and protecting consumers.

By implementing inventory serialization, retailers can optimize their supply chain management processes. Real-time visibility into inventory levels and product movements facilitates better demand forecasting, inventory planning, and efficient order fulfillment, resulting in cost savings and improved customer satisfaction.

Serialization is crucial in combating counterfeiting in the retail industry. Unique identification codes enable retailers and consumers to authenticate products, ensuring customers receive genuine merchandise. By curbing counterfeits, businesses can protect their brand reputation and maintain customer trust.

RFID Technology for Inventory Management

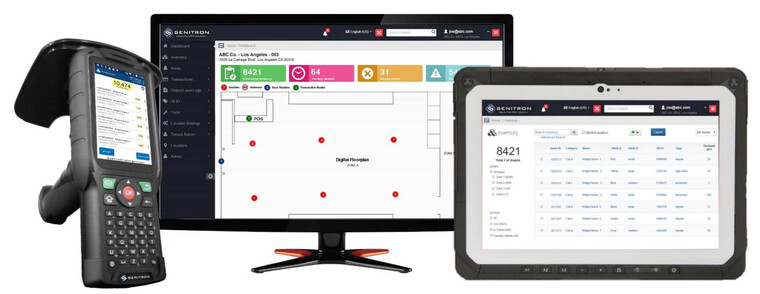

RFID (Radio Frequency Identification) technology is a powerful tool that complements inventory serialization in the retail industry. RFID tags contain electronically stored information that radio waves can read remotely. These tags can store more data than traditional barcodes, allowing quick and accurate inventory tracking.

Implementing RFID technology for inventory management offers several advantages:

RFID tags can be read simultaneously, allowing quick and accurate inventory counts. Retailers can perform inventory audits in a fraction of the time it would take with manual processes, reducing labour costs and minimizing disruptions to daily operations.

RFID technology enables real-time visibility into inventory levels, ensuring accurate stock replenishment and preventing stockouts. Retailers can proactively manage inventory levels, avoiding lost sales opportunities and optimizing working capital.

With RFID-enabled inventory management, retailers can improve the customer experience through features such as automated checkouts, self-service kiosks, and personalized recommendations. Faster and more accurate inventory tracking translates to improved product availability and shorter customer waiting times.

Conclusion

Combined with RFID technology, inventory serialisation empowers retailers with efficient inventory management capabilities. By assigning unique identifiers to individual products and utilizing RFID tags, businesses can achieve enhanced accuracy, improved traceability, efficient supply chain management, and counterfeit prevention.

These advancements lead to streamlined operations, reduced costs, and improved customer experience. Embracing inventory serialization and RFID technology is a strategic investment for retailers seeking to stay competitive in today's dynamic retail landscape.

|

|